CE ISO Certificates Plastic Granules Cutter Machine for Plastic Recycling

Overview Package Size 500.00cm * 200.00cm * 200.00cm Package Gross Weight 2700.000kg CE ISO Certificates Plastic Granule;

Overview

Application:PE/PP/PS/ABS Rigid flakes

Basic Info.

| Model NO. | ASE |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Ceramic Heater or Far-Infrared Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008 |

| Condition | New |

| After-Sale Service | Free Spare Parts |

| Final Product | Pellets/Granules |

| Factory Location | 2 Hours Drive From Shanghai |

| Sample/Service Manua | Available |

| Material | Iron |

| Electrical Appliances | European Appliances |

| Business Type | Manufacturer |

| Advantage | Famous Brand Motor |

| Capacity Range | 320kg/H-2100kg/H |

| Application | Film, Filament, Raffia, Foam |

| Control | P.L.C Control |

| Target Being Recycled Material | PE/PP/PS/ABS Rigid Flakes |

| Voltage | 380V 50Hz or Customized |

| Electric Components | ABB, Ls, Omron, or Customized |

| Machine Type | Recycling Machine |

| Transport Package | Wooden Pallet |

| Specification | Customzied |

| Trademark | ACERETECH |

| Origin | Jiangsu Zhangjiagang |

| HS Code | 8477209000 |

| Production Capacity | 100sets/Year |

Packaging & Delivery

Package Size 500.00cm * 200.00cm * 200.00cm Package Gross Weight 2700.000kgProduct Description

CE ISO Certificates Plastic Granules Cutter Machine For Plastic RecyclingProduct Description

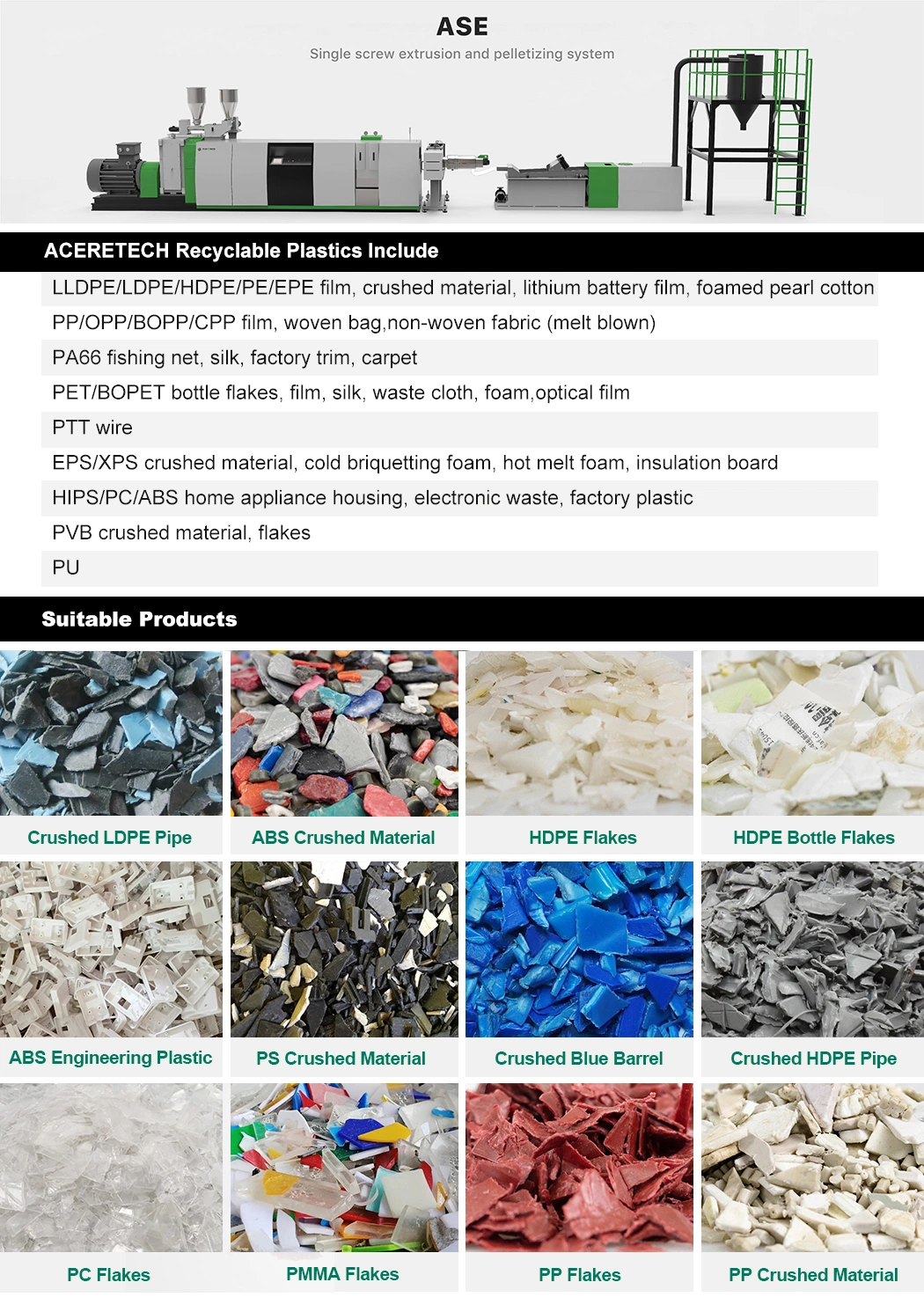

ASE single screw extrusion pelletizing system: This system is specially suitable for the rigid plastic scrap recycling and re-pelletizing. It can make the rigid plastics such as flakes, regrinds, crushed plastics into granules again with mild re-melting, volatilization and impurity filtration.Application:PE/PP/PS/ABS Rigid flakes

Product Parameters

| SPECIFICATIONS | |

| Machine Model | ASE |

| Target Recycled Material | HDPE,LDPE,PP,BOPP,CPP,OPP,PA,PC,PS,PU,ABS,PET Final Product Shape: Particles |

| Final Product Shape | Particles |

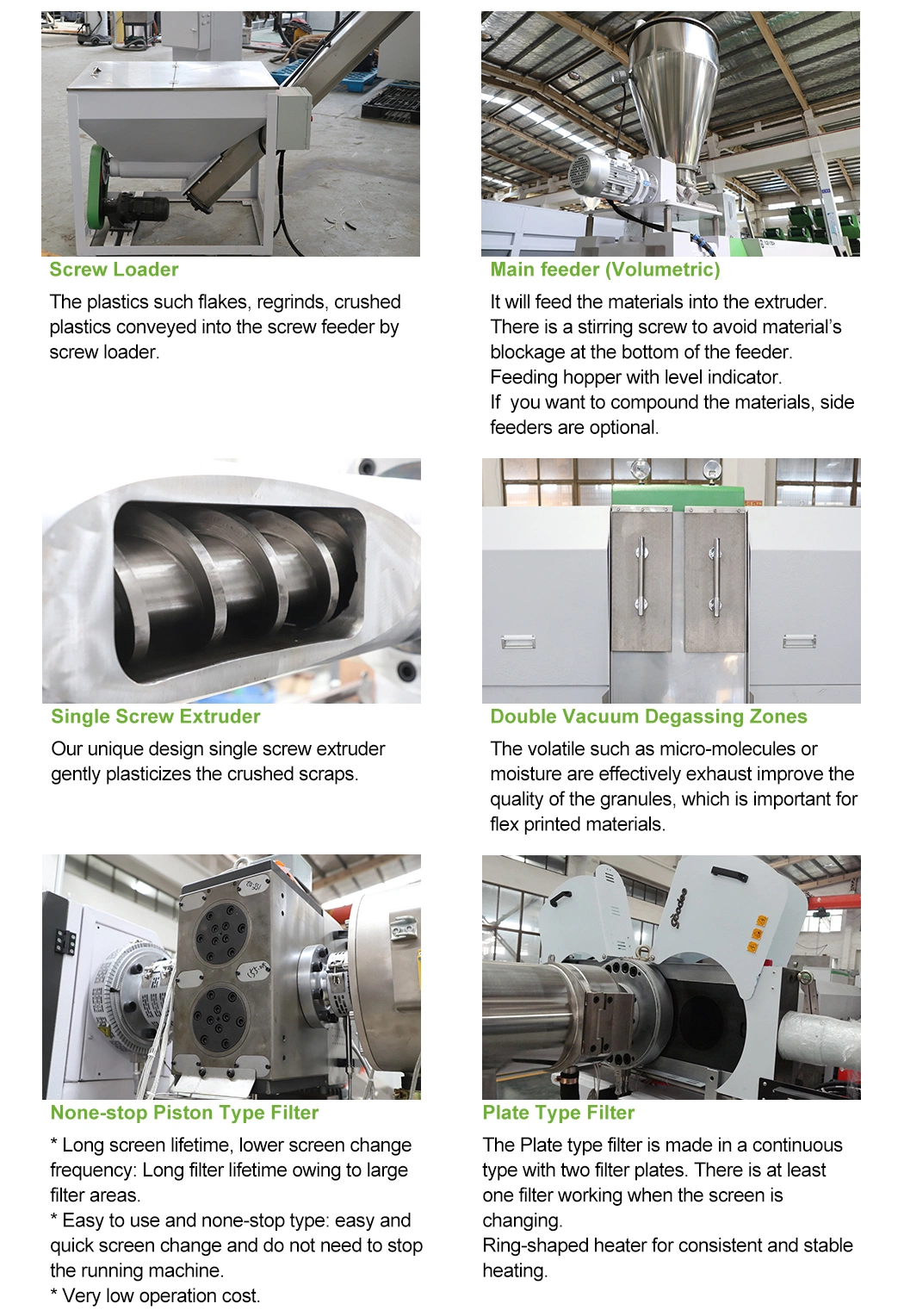

| System composition | Screw Loader, Single Screw Extruder, Filtration first, Vacuum Degassing, Pelletizer, Water Cooling Device, Dehydration Section,Conveyor Fan, Product Silo. |

| Output Range | 120kg/h-1000kg/h |

| Feeding Device | Belt Conveyor (Standard), Roll Hualing off device (Optional) |

| Diameter of Screw | 80mm-180mm |

| Material of Screw | Bimetal |

| L/D of Screw | 38/1 |

| Heater of Barrel | Ceramic heater or Far-infrared heater |

| Cooling of Barrel | Air cooling of fans through blowers |

| Vacuum Deashing Exhaust | Two Double-zone vacuum degassing system (Standard) |

| Pelletizing Type | Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing |

| Voltage Standard | According to the Voltage of the Customer's Location |

| Optioanl Device | Metal detector, Roll hualing off device, Masterbatch and additives feeder |

| Warranty | 13 months from the date of bill of lading |

| Technical Services | project design, factory construction, installation and recommendations, commissioning |

| Parameters | ||||

| Machine Model | Screw Diameter(mm) | L/D | Extruder Motor(kw) | Output Capacity(kg/h) |

| ASE80 | 80 | 38 | 55 | 120-160 |

| ASE100 | 100 | 38 | 110 | 260-350 |

| ASE120 | 120 | 38 | 160 | 330-480 |

| ASE140 | 140 | 38 | 200 | 550-650 |

| ASE160 | 160 | 38 | 250 | 600-800 |

| ASE180 | 180 | 38 | 315 | 800-1000 |

Product Details

Company Profile

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

You may also like

Send inquiry

Send now